Speed Humps are designed as traffic calming devices. Type 2 Speed Humps in particular focus on improving safety conditions for all car parks users including vehicles and pedestrians. Their effectiveness in car parks around Australia is somewhat disputed however. The following article will discuss five factors that contribute to a Speed Hump's effectiveness in Australian car parks.

Type 2 Speed Humps are often found in car park areas such as:

· Multi-story car parks

· Covered area car parks

· Hospitals

· Airports

· Child Care facilities

· Schools and school car parks

· Parks and public gardens

· Factories and Workshops

· Shopping Centers

· Retirement Villages

· Service Stations

· Drive-through fast food restaurants

In Australia, vehicle drivers are conditioned to understand the visual cues associated with speed humps. The bright yellow-on-black pattern is distinct, and the automated response to such a pattern is – generally speaking – to slow down. The Australian Government have stated that speed humps are indeed effective at slowing driver in the confined spaces of a car park. Evidence has indicated that a decrease in speed frequently leads to a reduction in the number and severity of accidents in these areas. The vulnerability of surrounding pedestrians is also reduced in areas with effective speed hump controls.

In car park areas, tight conditions make speeding a cause for numerous accidents each year, involving both vehicles and pedestrians. While car parks are generally low speed environments, they are full of a wide range of hazards and distractions that can intensify the severity of speeding infractions. Depending on the layout of a car park, speed humps may be required to limit a driver’s ability to speed during long, straight stretches or at entrances and exits.

FIVE Steps to Ensure Maximum Effectiveness

1. Purchase the right product for your needs

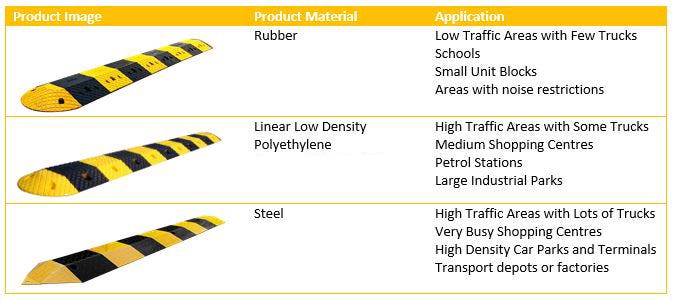

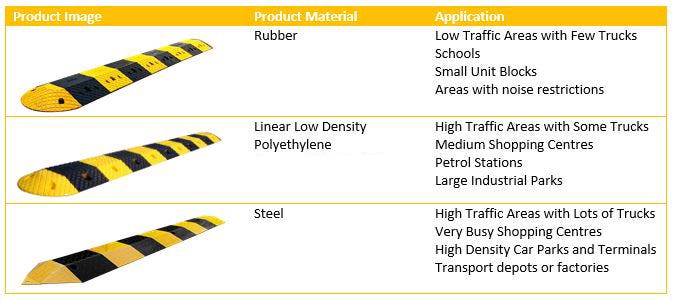

It is important to choose appropriate product materials and bolts depending on the factors of application and intended surface of installation. Speed Humps in Australia can be found in varying materials, as shown in the table below. The various applications mentioned are dependent on the strength and durability of each material, and the quality of manufacture processes used.

Material

Rubber Speed Humps are effective in low traffic areas, and are a cost-effective and highly durable material. It is also great at absorbing sound in noise-restricted areas. However, these products are least able to endure heavy vehicle traffic, and over-use can cause the material to indent permanently and become unusable.

Linear low density polyethylene (LLDPE) is a far more durable alternative to rubber, making it ideal for areas with higher traffic. This material is less effective at absorbing noise, yet it is far lighter and easier to install, and can be less of a 'slip and trip' hazard when wet. When manufactured at high quality and installed appropriately, LLDPE Speed Humps can match the durability of steel alternatives at a far lower price.

Steel Speed Humps are the most durable in specifically high-traffic areas with a large percentage of trucks and heavy vehicles. As a result however, steel material also comes with a higher price tag, and is heavier than LLDPE alternatives. Bronson's Safety Note: Steel Speed Humps are not appropriate for placement in Service/Petrol stations, as they a can be a spark hazard.

Fixing Bolts

Choosing the right bolt for the specific ground surface is extremely important. Despite the quality of Speed Hump material, if an inadequate bolt is used for the specific ground surface, the speed hump is likely to become dislodged. This causes it to move around, becoming a hazard and a liability.

The two top-rated Speed Hump bolts are:

Sleeve Anchor Bolt (Dynabolt): These zinc plated bolts are ideal for concrete surfaces. The versatile anchor system digs thoroughly into the concrete surface, staying put for extremely long periods of time. Dynabolts are appropriate for rubber and metal materials, but should not be used with LLDPE Speed Humps.

Hex Anchor Bolt and Hilti Plug: The unique anchor design on these bolts are perfect for both concrete and asphalt surfaces. The zinc plated steel will never rust, making it a long lasting option. These are also suitable for all three Speed Hump materials.

Bronson Fact: Speed Humps should not be installed on loose gravel surfaces. No bolt type is suitable to hold the speed hump in such a surface for long periods of time. As wheels push against the speed hump, the gravel beneath shifts around. This forces the bolts loose, becoming hazardous.

2. Know the Law and Requirements

WHS laws are strict in Australia, and actually vary depending on which state or territory a business is residing in. Before purchasing or placing a Speed Hump, it is recommended that all Australian businesses consult the relevant WHS laws to confirm compliance. Check them out here.

Australian Standard AS2890.1:2004 outlines the following specifications for Speed Hump design in Australia:

-

The angle height to length ratio must be 1:2, to ensure a steady incline for all vehicles.

-

A speed hump must follow a clear colour pattern of alternating Yellow (or white) and Black sections that are 250mm wide.

-

Type 2 speed humps must be between 25mm to 75mm high.

-

A speed hump must have a flat top that is between 100mm to 150mm wide.*

These requirements are extremely important for ensuring the product is appropriate for all possible user vehicles. Before purchasing a speed hump product, it is recommended that a purchasing officer ensure that all these requirements are met.

*Did you know? If your Speed Hump is rounded on top, it is illegal in Australia. If an accident occurs involving a round-top Speed Hump, the business owner is fully liable. Don't get caught out, get compliant!

3. Choose Quality over Quantity

A low quality safety item can have detrimental effects on a businesses' workers and their customers or clients. Poorly-made and designed Speed Humps will warp, crack and fall apart at an accelerated rate, increasing maintenance costs. This may also cause damage to user vehicles and tyres, and will likely be a less effective method for calming traffic.

Safety is worth the investment. Purchasing from a reputable business is one way to guarantee that a Speed Hump, or any safety equipment, is high quality. Checking a businesses location and reading recent reviews are generally good methods for ensuring high quality products.

As a general rule, it is recommended not to purchase safety products from a supplier if:

-

They have few or no reviews.

-

The company or product reviews are mostly negative.

-

They are located overseas and/or in an area with less strict safety requirements.

-

They do not reference compliance with specific Australian Standards (AS2890.1:2004).

-

The price seems "too good to be true".

A higher quality speed hump will have a higher price tag, but will also have reduced maintenance costs and liability costs. If a company is working with a strict budget, it is recommended that they keep an eye out for sales or discounts with reputable companies. Never is there a circumstance where it is appropriate to settle for low quality, where the safety of road users and pedestrians is involved.

4. Position Appropriately

There are strict requirements for placing and spacing Speed Humps. The three major positioning requirements for Type 2 Speed Humps are as follows:

-

Along a single aisleway in a car park, Speed Humps must be spaced no less than 10 metres apart. Primarily, this requirement ensures that all vehicles are able to pass the first speed hump before beginning a second. It also ensures a steady flow of traffic.

-

Speed Humps must not impede pedestrian or wheelchair traffic. At least one metre of travel space is required beside a speed hump, when placed in an area that is used by pedestrians. This is required to ensure that an accessible travel path is provided for people with disabilities, parents/guardians with prams or other pedestrians with shopping carts. However, one metre spacing on either side is not required when reasonable pedestrian and wheelchair access is provided elsewhere (see image below).

-

Speed Humps must be located clear of intersections and roadways. In a car park, Speed Humps must not impede parking cars, or cars travelling in alternative directions. Speed humps can be placed at entrances to car parks, to ensure an appropriate speed when entering the hazardous environment. Positioning is very important and can mean the difference between being compliant and potentially breaking the law (see image below).

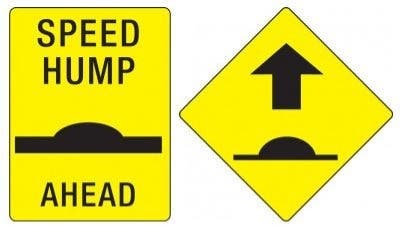

5. Utilise Signage

Speed Humps must be accompanied by appropriate signage to alert drivers of the upcoming speed decrease. Without appropriate signage, Speed Humps may not be seen until it is too late for a vehicle to decrease their speed. This is known to result in accidents, vehicle damage and other property damage.

Best practice indicates that:

-

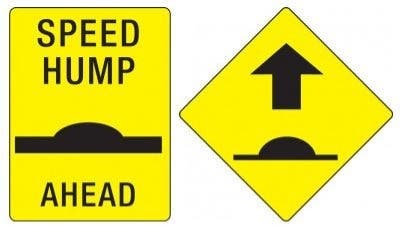

A 'Speed Hump' (example below) sign should accompany a speed hump.

A 'Speed Hump Ahead' (example below) sign should precede a Speed Hump by approximately 30 to 50 metres.

A speed limit sign or 'reduce speed' (example below) may also be used to denote the intended speed of a certain area. These signs are often used in conjunction with Speed Humps to further enforce a reduction in speed.